Tolerancing for Aluminium Extruded Profiles EN and ISO standards

Geometric Dimensioning and Tolerancing (GD&T) is the common, powerful language of industrial manufacturing. GD&T is recognized around the world as the only way of defining engineering drawings and CAD models efficiently and unambiguously. But the unfortunate reality is that most of the workforce that engages with mechanical drawings has an adequate understanding of this language. Many individuals and organizations get by for some time before costly or otherwise painful experiences convince them they need to improve their skills in use of GD&T.

The truth is that properly applied at the earliest stages of a product development project, GD&T can establish robust product quality, save months of development time, tens even hundreds of thousands of euros, and potentially millions over the lifecycle of a product.

GD&T training has real benefits: lower costs, less non‐conforming parts, higher tolerances.

InQuality, authorized partner of HEXAGON MI, offers on‐site and on‐line GD&T training courses.

Based on the latest ISO & ASME standards, our courses are tailor‐made to fully cover your particular needs.

.

.

Aims & Objectives

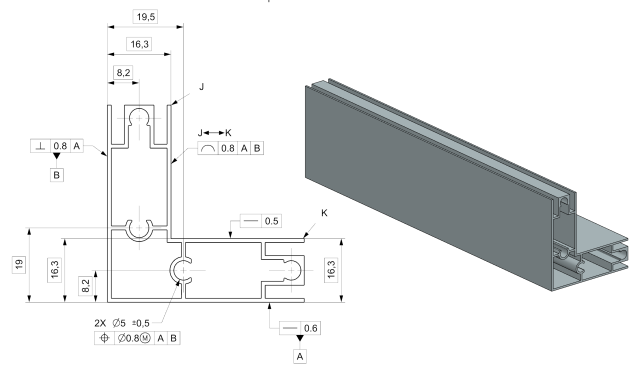

The course is delivered as an intensive, two‐day programme that focuses on the fundamental concepts of tolerancing for aluminium extruded profiles as per EN 755‐9:2016 & EN 12020‐2:2016 and ISO standards. Participants will learn the application of concepts and rules defined in the set of current tolerancing standards from a practical point‐of‐view, discover how the system of dimensional and geometrical tolerancing works, find out the pitfalls, ambiguities and misconceptions that rely on the standards interpretation and gain confidence on how they will be able to overcome them. This highly‐interactive course includes extensive classroom discussions, team exercises and problem‐solving sessions. Examples of drawings or components from the client, where available, are used in order to illustrate the course material. Customization of the course to specific participant needs can be discussed. To maximize the effectiveness of the training, an upper limit to the class size of 10 delegates is recommended.

Course topics

- Introduction to dimensional and geometrical tolerancing

- axiom of manufacturing imprecision, interchangeability in industry, the role of standardization

- Standards in context

- EN 755‐9:2016 and EN 12020‐2:2021 (2016)

- ISO 6362 series of standards (ISO 6362‐3:2022, ISO 6362‐4:2022 and ISO 6362‐5:2022)

- ISO GPS (Geometrical Product Specification) system vs. EN, DIN and relevant national standards

- What is Geometrical Tolerancing?

- benefits and advantages of Geometrical Tolerancing

- major pitfalls of traditional tolerancing and how to overcome them

- Tolerances for aluminium extruded profiles as per EN 755‐9:2016 & EN 12020‐2:2021 (2016)

- tolerances on dimensions (wall thickness, A, B, C, E, H dimensions)

- tolerances on Form (straightness, convexity, concavity)

- tolerances on Orientation (parallelism, angularity)

- tolerances on Profile (contour, twist)

- Ambiguities and misconceptions on EN 755‐9:2016 & EN 12020‐2:2021 (2016)

- ambiguous terms and definitions lead to ambiguous requirements

- typical inspection and verification problems and how to overcome them

- The concept of Features and Features‐of‐Size (ISO 17450‐3:2016)

- Linear and angular size tolerances clarified

- ISO 14405‐1:2016, ISO 14405‐2:2018 and ISO 14405‐3:2016

- Size vs. Form: the Envelope Requirement

- Datums and datum systems (as per ISO 5459:2011 and ISO/DIS 5459.2:2017)

- what is a datum and why is it needed?

- datum and datum features, indicating datums on drawings, annotation and symbology

- Tolerance frames

- tolerance symbols, tolerance frame modifiers, tolerance frame on the engineering drawings

- 3D‐CAD Model Based Annotation (MBD) (as per ISO 16792:2021) and 3D‐PMI

- Tolerance characteristics (including what they will and won’t control – ISO 1101:2017)

- tolerances of form, orientation, location and profile ( ISO 1660:2017)

- Finding your way through the tolerancing system – understanding how each tolerance type works