One more successful installation of the inline Surface inspection PROMEX CYRUS from ASCONA & DCUBE at ETEM GESTAMP in Bulgaria.

Since 2019, Etem Group and Gestamp Group have entered into an agreement concerning the creation of a joint venture focused on the extrusion and processing of aluminum profiles in the automotive industry. Gestamp, with a presence in more than 23 countries, is an international group dedicated to designing, developing and manufacturing metal automotive components and Etem Group, a leader in aluminum extrusion with more than 50 years of experience and continuous presence in the design and production of aluminum profiles.

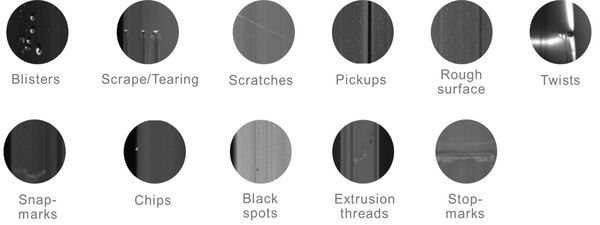

When it comes to automotive profile production for major car manufacturers, surface quality is of paramount importance. This was exactly the case with the Etem Gestamp and their huge interest in producing zero-defect aluminum profiles.

In order to leverage this challenge, the German company ASCONA, the world leader in optical profile measurement technology and the Greek spin-off company D-Cube, experts in Computer Vision and Artificial Intelligence, have teamed up and launched Promex CYRUS. Promex Cyrus is a Machine Vision System for real-time inline Surface inspection and quality control of Aluminium profiles. Its innovative technology is based on a holistic AI framework specially designed for the aluminum extrusion industry.

Promex Cyrus is the only solution in the world that guarantees early defect detection, prevents unnecessary downstream processing, and can be successfully applied to all aluminum industries, ensuring maximum production efficiency. The system is operating successful in production environment at ETEM Gestamp for more than one year with proven accuracy, efficiency and reliability.

I would like to express my utmost satisfaction with the AI optical surface defect detection system purchased from ASCONA- D-CUBE and InQuality, which we have installed at our aluminum extrusion press. The system’s performance has exceeded our expectations, consistently identifying and highlighting surface defects with remarkable precision, contributing significantly to our quality control efforts. Its intuitive interface has streamlined our operator’s workflow, making it easy for them to navigate and interpret results efficiently. A proven versatility in handling various surface textures and finishes on aluminum has been demonstrated, showcasing its adaptability to our diverse product range.

I would like to extend my appreciation to D-CUBE team for their support during the implementation phase and their responsiveness to our specific requirements.

We are looking forward to a continued collaboration with D-CUBE-ASCONA & inQuality team.

Nikolaidis Anastasios

Quality & Sustainability

Senior Manager

Etem Gestamp