What is the GD&T?

As the requirements of manufactured products become ever more demanding, the need to be able to define those requirements precisely, completely and unambiguously becomes ever more crucial. In order to meet this need, a complete system is defined across a wide number of interlinked international and national standards which are of paramount importance to modern industry. This system is the Geometric Dimensioning and Tolerancing (GD&T).

As the requirements of manufactured products become ever more demanding, the need to be able to define those requirements precisely, completely and unambiguously becomes ever more crucial. In order to meet this need, a complete system is defined across a wide number of interlinked international and national standards which are of paramount importance to modern industry. This system is the Geometric Dimensioning and Tolerancing (GD&T).

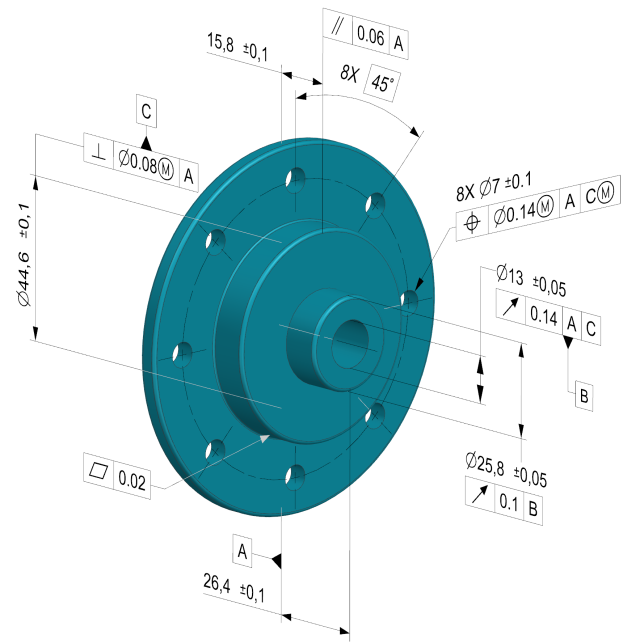

Geometric Dimensioning and Tolerancing (GD&T) is a precise language of engineering symbols that clearly communicate the design intent of the part. GD&T is recognized around the world as the only way of defining engineering drawings and CAD models efficiently and unambiguously.

Geometric Dimensioning and Tolerancing (GD&T) is now the common, powerful language of industrial manufacturing. Is the widely-accepted, internationally standardized language of symbols used on engineering drawings and CAD models. It is the language that empowers engineering design to define in a complete, clear and unambiguous way the geometry of any part and to communicate its allowable variation (tolerance).

The ISO system of Geometrical Product Specification & Verification (ISO – GPS), along with the ASME system of Geometric Dimensioning and Tolerancing (ASME – GD&T), have been developed over the last years, and are still evolving today.

The main target of GD&T is to tear down the walls of misunderstanding by having a common engineering language.

What are the benefits of using GD&T?

GD&T improves design accuracy by allowing appropriate tolerances that maximize production. It forces the designer to fully consider the manufacturing process and inspection methods.

The result is on the one hand greater tolerances that guarantee proper operation, and on the other hand a reduction in manufacturing and inspection costs. Also, the “bonus” or extra tolerance under certain conditions can lead to significant production cost savings.

GD&T’s clear, comprehensive and concise data & symbols are easily adaptable to almost all digital CAD part design software.

GD&T as a single and consistent language reduces the potential for misinterpretation. Today’s complex engineering designs require the most accurate, reliable and unambiguous interpretation. GD&T allows designers, manufacturers and inspectors to communicate clearly with each other. This saves time and makes production & inspection processes much more efficient.

The result is that stability is ensured in all phases, from design to production.

GD&T ensures that all dimensional & tolerance requirements will be met.

By stating all design requirements explicitly and clearly, the designer guarantees that all dimensional and tolerance specifications are accurately met.

The trainer

The background and teaching skills of the instructor are the most important factors in selecting a training provider. Especially in the demanding field of GD&T, you need someone with extensive GD&T experience, but also with a lively and down-to-earth style.

George Kaisarlis Ph.D., M. Eng

Our Trainer, George Kaisarlis, Ph.D., M. Eng., has more than 25 years of training and industrial experience in the fields of GD&T, precision manufacturing and industrial dimensional metrology.

His experience in industry mainly comes from his long career as a field engineer for the Hexagon MI group and from the provision of specialized technological services for the manufacturing industry (reverse engineering, dimensional metrology, machine design and product development).

He has conducted GD&T and dimensional metrology classes for a variety of manufacturing clients throughout Europe and the Middle East.

Dr Kaisarlis is active as an appointed Technical Expert (WG2/WG10/WG17/WG18) and as an accredited national delegate (ELOT/NQIS) in ISO Technical Committee (TC) 213 “Dimensional and geometrical product specifications and verification”. ISO TC/213 is responsible for the international standards for Geometrical Product Specification and Geometrical Tolerancing.

Dr Kaisarlis also holds a research and teaching assistant’s position in the School of Mechanical Engineering of the National Technical University of Athens (NTUA), Greece. With this affiliation he is active in several research projects and has authored numerous scientific articles in refereed journals and scientific conferences [https://orcid.org/0000-0002-4990-9579].

Dr Kaisarlis holds a M. Eng. Degree in Mechanical Engineering from TU Athens (NTUA) since 1997, and a Ph.D. degree from the same University since 2007.