The Customer |

Vascar is one of the main canned meat producers in Romania with more that 30 years of experience in the industry. In the highly competitive world of canned food production, ensuring quality and safety are paramount. VASCAR recognized the need to take their quality control to the next level and decided to partner with InQuality to implement the double seam inspection system by Industrial Physics.

The Challenge |

Vascar has always strived to deliver top-quality canned products to its customers. The inspection of double seams in canned food products is a critical step, but their existing methods were time-consuming and operator dependant.

The Solution |

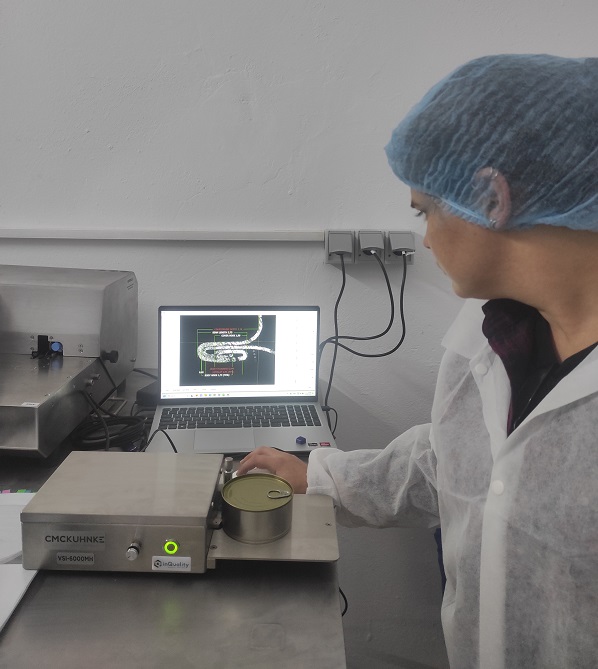

To address these challenges, inQuality recommended the SEAMscan SPC System double seam inspection system by CMC-KUHNKE and the automatic seam saw by QUALITY BY VISION, both brands of the Industrial Physics group.

The SEAMscan SPC System is a manually operated, high-resolution tool for double seam inspection and measurement with SPC Reporting. The double seam inspection kit SEAMscan SPC, measures seam thickness, seam height, countersink depth, seam gap, body hook, cover hook and overlap.

The package includes:

- Video Seam Imager – Clearly illuminates & captures images of seams with high-resolution USB camera & precision optics

- SEAMview Inspection Software – Capture, measure & save seam images

- Visionary SPC Software – Easy-to-use Statistical Process Control for quick analysis of can inspection data

Combined with the automatic Seam Saw the sample preparation time is close to zero. The automatic seam saw provides the perfect cut without disrupting the shape and the characteristics of the double seam for evaluation.

Implementation |

The installation process was seamless, and the system was integrated into the quality control lab at VASCAR. The quality control department quickly learned the aspects of the software and it’s many capabilities. From now on they can evaluate their results through a high resolution camera and proceed with the analysis of them.

Key Benefits |

1. Improved Precision

Its ability to identify even the most minor imperfections ensure that the canned products leaving the production line are of the highest quality and safety standards.

2. Efficiency in Quality Control

The manual operation of SEAMview, combined with the SPC software, allowed for an efficient quality control process. This meant that inspections were not only precise but also swift, contributing to the overall efficiency of production.

3. Comprehensive Data Analysis

The SPC software package was a game-changer for VASCAR. It provided detailed data on each inspection, allowing the company implement necessary adjustments for continuous quality improvement.

Conclusion |

The successful installation of the double seam inspection system by InQuality has improved precision, and provides VASCAR with the data needed for continuous quality enhancement.

Click here to learn more about seam inspection of the double seam by INDUSTRIAL PHYSICS