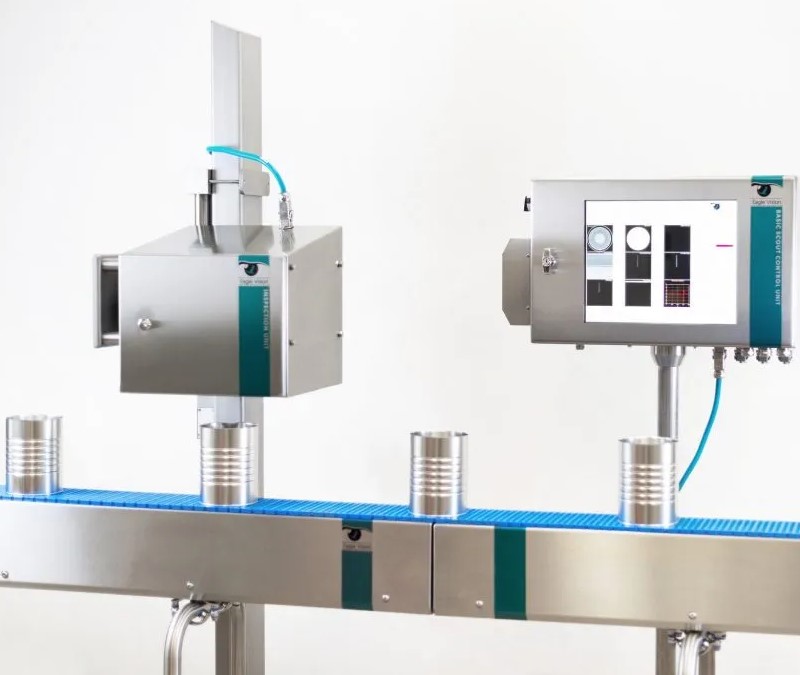

Empty Can Inspection - INDUSTRIAL PHYSICS EAGLE VISION

The Empty Can Inspection system is able to detect defects quickly and accurately on the flange, bottom and the inner sidewalls of the can.

SKU: Empty Can Inspection

Description

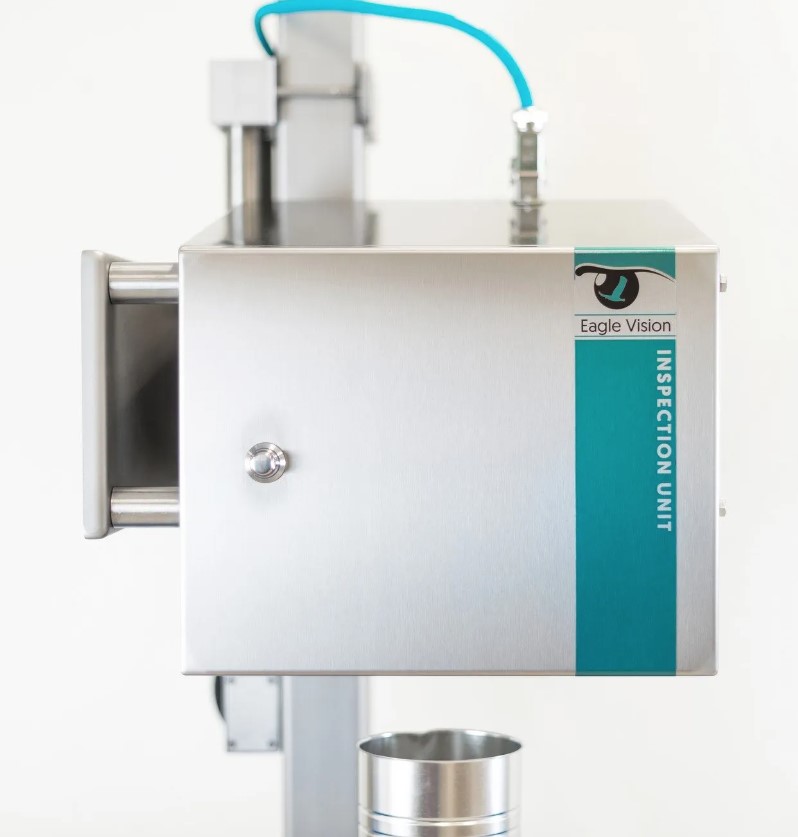

The Empty Can Inspection system is able to detect defects quickly and accurately on the flange, bottom and the inner sidewalls of the can. Pollution and spots inside, as well as flange dents, flange width and ovality/roundness are being inspected. The Empty Can Inspection system is available for high speeds. The system is compact and can easily be installed on both existing and new lines. Pollution and spots on the inside, as well as flange dents, flange width and ovality/roundness are being inspected.

Functions:

• Inspection of flange: damages, dents, flange width and ovality/roundness

• Inspection of inner bottom and inner sidewall for pollution, spots, damages and foreign objects

Options:

• 360° Can Inspection on the outside of the can

• Seam Inspection

• Scoop Inspection (for scoop inserts)

- Short start-up time by using simple presets

- Short changeover time by using simple presets, product library or MES input

- High speed available up to 144.000 p/h

- High resolution available

- Compact system

- Various can sizes and can types possible

- Stainless steel hygienic design

- Used by Can Fillers & Can Makers

- Automatic Height adjustment available

- Easy maintenance due to absence of moving parts

- Proven standard system

- Network connection

- Very operator friendly user interface

- Optional custom language on user interface

- Storage statistics and pictures

- Modular set-up

- Low cost of ownership

- Simple installation in the line

- Hygienic Design

- CE certified