In-line Seam Inspection INDUSTRIAL PHYSICS EAGLE VISION

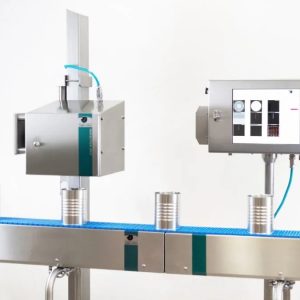

The Seam Inspection module inspects the complete seam around the can. The module is positioned in-line to inspect 100% of the produced cans, non-destructively.

Description

The In-line Seam Inspection module inspects the complete seam around the can. The module is positioned in-line to inspect 100% of the produced cans, non-destructively. Various can sizes and can shapes are inspected without any product handling. The inspection is available for high line speeds.

Functionalities:

• Droops

• V-shape, U-shape, Spur, Lipper

• Double ends

• Incomplete seam

• Mismatch

• Wooling and particles from seamer

• Seam dents

• Seam dent plate fracture

• Pulled seam

• Knocked down flange

• Knocked down curl

• Pressed compound

• Cut seam

• Cracked seam

• Torn flange

• Plate fracture in double seam

• And other visible defects

- In-line inspection of seam

- Inspects 100% of the produced cans

- Non-destructive

- No product handling needed

- High speed available (up to 90.000 products per hour)

- Different can sizes and shapes, including round and rectangular cans

- Modular expandable with other inspection modules

- Network connection

- Remote connection

- Storage of statistics and pictures

- Short changeover time

- Simple installation to the line

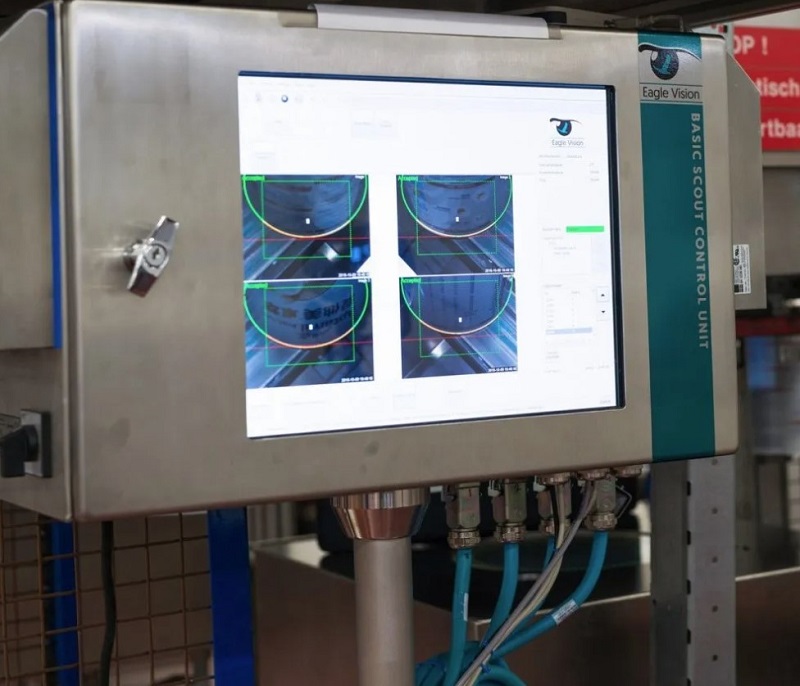

- Stainless steel hygienic frame

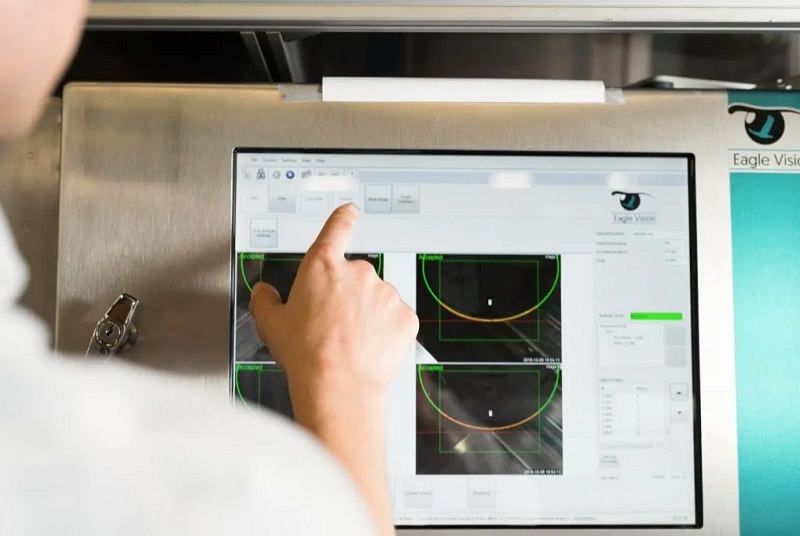

- Very operator friendly user interface

- Easy maintenance due to absence of moving parts

- Mandatory by Canadian Food Inspection

- Complies Canadian Food Inspection Agency for sea food cans

- Hygienic Design

- CE certified