Code Reading - INDUSTRIAL PHYSICS EAGLE VISION

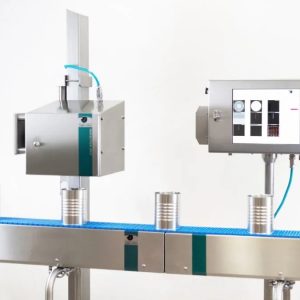

The Code Reading modules inspect ink-jet, laser, thermal-transfer and pre-printed ID codes on various packaging types, including infant formula cans, food cans, beverage cans, labels, cartons, PET bottles, films and foils.

Description

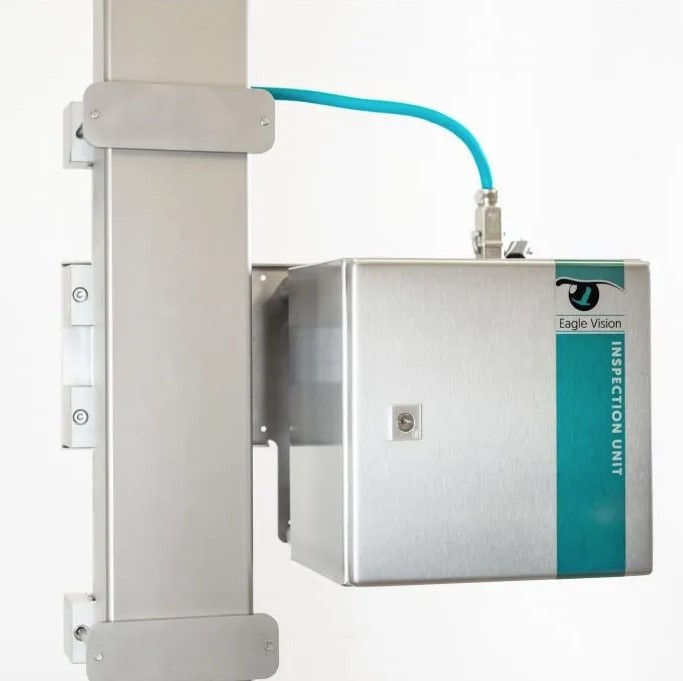

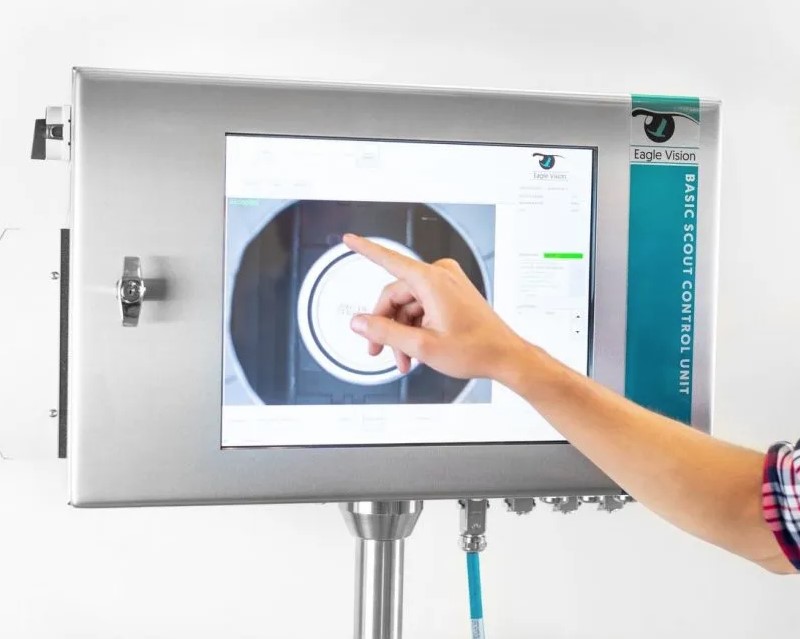

Code Reading assures you compliant best Before Dates and Lot Codes, detection of mixed-up packaging and registration of serialization anti-fake codes. It has special modules dedicated for reflective or round surfaces, like cans and bottles. Delivering standard solutions ideal for High Speed performance, up to 144.000/hour, as required in the beverage industry. Most of solutions can run fully automated, fitting the Industry 4.0 movement.

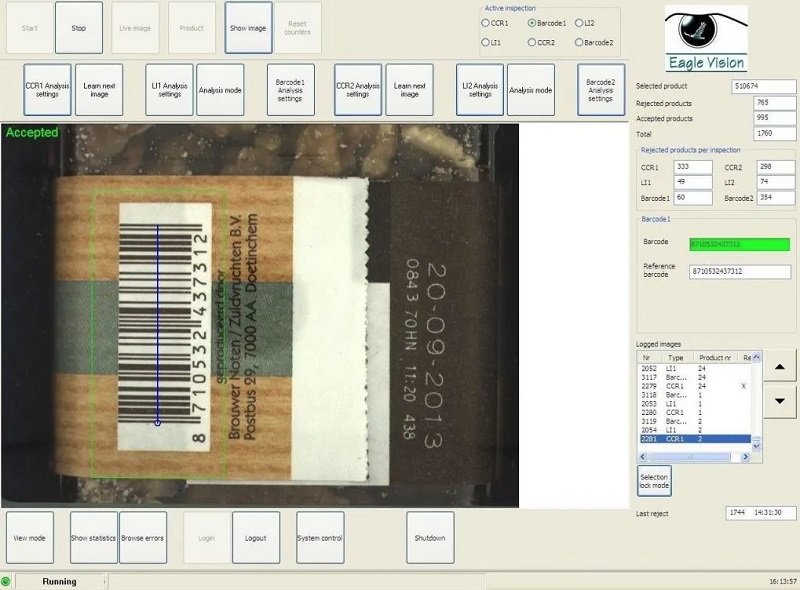

Our Eagle Vision Code Reading modules can detect incorrect, incomplete, and unreadable codes. To assure inline printings, detection of mixed packaging and serialization anti-fake readings.

No matter the reflecting surface of the packaging, we’ll have an easy-to-use advanced inspection solution.

Code-reading is vital for production lines. Products have codes for communicating the Best Before Date and Lot code, as well as for packaging identification and traceability purposes. Types of codes that Eagle Vision systems can read:

- Production dates

- Best Before dates (BBF)

- Shelf-life codes

- Lot codes

- Batch codes

- Track & trace codes

- Packaging label identification codes

- Barcode

- 2D Data Matrix codes

- QR codes

Typical code defects in production processes can include:

- Incomplete code

- Missing code

- Incorrect code

- Ink drops and contamination

- Interference of multiple codes

- Mis-positioned code

- Misprints

- Moisture drops in code

- Obstructed nozzle failures

- Stretched or squeezed code,due to variations in line speed

- Trigger failures of the coding device

Options given by Code reading module:

• Reading multiple codes and code types at the same time.

• Label ID numbers (MRDR code / OCR code)

• Packaging identification codes

• Serialization codes (unique code per product)

• Decoration, Color Art-work, or Label Inspection

• Cap Inspection (mix-up / positioning)

• Fill-level Inspection

• High resolution and multi-camera configuration for small code types, bigger inspection surfaces, multiple viewing points and 360° view on round products

• OCR, OCV and Code presence detection

• Inspection of special font types, including Asian and Arabic fonts

• Verification of code position

• Misprints and ink drops

• Ink-jet, laser, thermal-transfer, pre-printed codes

• Production code, Best Before date, 2D Data Matrix code, QR Code

• Barcode Reading (ladder + picket fence orientation)