Leak, Burst, O2 & CO2 Tester Check-A-Pack 222 RDM

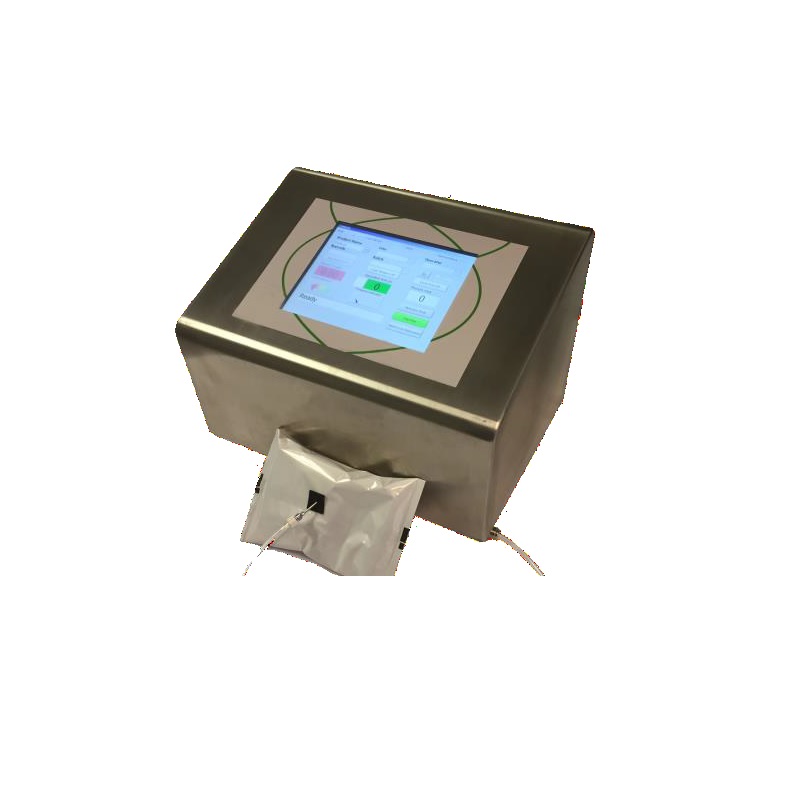

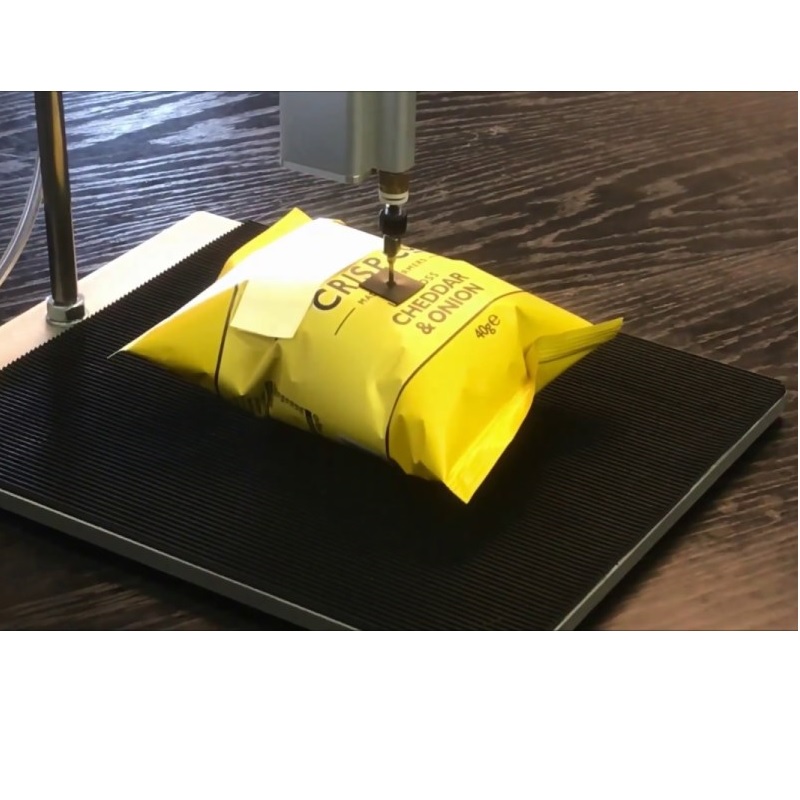

The Leak, Burst, O2 & CO2 Check-A-Pack 222 RDM, is a benchtop model with manual sample preparation.

SKU: CAP222 LBOC

Description

This equipment is essential for measuring the slip properties of packaging materials to ensure smooth running on production packaging machines or to measure the effect that a coating or print has on the base material.

The new CF-800XS features the latest in design and technology for machine set up, testing, measurement, and recording using touch panel screen display units. The constant, smooth lead screw-driven cross arm ensures reliable and repeatable measurement.

Other benefits include: Vacuum suction on the bed to clamp the material, optional temperature control circuit to heat the bed for `hot slip´ values, together with analog recorder output and RS232 output for either chart recorder logging or computer data logging of results.

Standard accessories:

- 200g 63.5mm x 63.5mm sled

- Sled / Bed Templates

- Check weight

- Sled links

- Magnetic strips

- Bed Material: Natural anodized cast aluminum

- Sled Material: Anodised aluminum with foam contact pad with a density of 0.25/cm

- Speed Control: 10 – 1000mm/min +/- 10mm/min

- Force Reading: 0-1000.0 grammes +/- 0.25% Fro (other loads can be specified)

- C of F Reading: Calculated value from sled used 0-1.00 +/- 0.25% Fto

- Touch Panel Screen: LCD, 256 Colour, QVGA, 320 x 240 pixels, 14.48cm diagonal viewing. Touch screen, analog resistive (gonze) with serial controller Processor Geode SC2200. 266 MHz MMX compatible. 2 Mbyte, onboard flash memory for firmware 64 MB Dram main memory

- Vacuum: Air pressure of 80 – 100 PSI supply with venture generated vacuum pulling +90 % vacuum

- Temperature: Ambient to 100ºC +/- 5ºC (when specified)

- Drive: DC synchronous motor/gearbox driving ball screw and crosshead

- Speed Feedback: Via in line encoder

- Output: RS232 C

- Power: 240 VAC single phase 50/60 Hz (110V AC available on request) 0.75 KW max

- Environment: 5-50°C ambient operating temperature, RH 75% max (noncondensing)