Clearance Gauge: Double Seamer Setup and Adjustment System - INDUSTRIAL PHYSICS QUALITY BY VISION

The Clearance Gauge helps optimize the can seaming process by taking out variations between the different seamer heads and looking at the seamer itself.

SKU: CLR-000007

Description

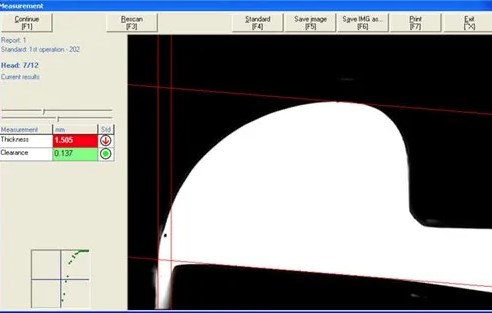

The Clearance Gauge is an easy and accurate solution for setting up your seamer. The camera takes the guesswork out of setting up the seamer by automatically measuring the seamer clearance and thickness. By minimizing downtime, this is especially useful for setup during changeovers and for daily use to make adjustments as the seamer warms up. The Clearance Gauge helps to determine which roll needs to be adjusted when a seam problem come up.

The Clearance Gauge is able to not only quickly and accurately set up the seamer and fix issues that come up from time to time, it makes sure that all seamer heads are performing perfectly and identically. This means that seamers will run better, and require adjustments less often and less downtime! Not only are you saving time – you are also reducing unplanned stops.

Instead of focusing on checking seams after the double seam is already complete, it helps optimize the can seaming process by taking out variations between the different seamer heads and looking at the seamer itself!

It is compatible with most seamer models, including most Angelus, Continental, Ferrum seamers and many more. Whereas most settings on the double seamer, such as lifter pressure and height are relatively easy to adjust and control, the roll to chuck relationship is difficult. Until today, seamer mechanics used feeler gauges, but the process was long and very inaccurate – resulting in bad and inconsistent seams, seamers going out of specs quickly and various problems that could not be easily traced.

The Clearance gauge solves all of these problems by offering an easy solution to seamer setup and adjustment.

• The Clearance Gauge not only quickly and accurately sets up the seamer and fixes issues, but also makes sure all seamer heads are running perfectly and are identical to each other.

• The Clearance Gauge is suitable for food & beverage fillers of all sizes. The gauge comes with all the software needed for measurement as well as databasing of images and a suite of reporting and SPC. The gauge connects directly to any PC via USB.

• Specs loaded into data base for quick and easy seamer set up

• Directs operators up/down to the specification

• Used for both 1st and 2nd operation seaming rolls

• Database allows for reports, images and head comparison which can be printed or save as PDF

• Can be used for any size can (separate chuck fit required per diameter)

• Detect worn or damage chucks and rolls

• Plug and play with any Windows 10 laptop or tablet

• Portrait and landscape mode available on tablet

• Calibration piece included

• System supports individual tracking of set up per head on multiple lines

- Number of seamer specs allowed: Unlimited

- Sizes: Compatible with nearly all chuck/roll seamers

- Measurement Resolution: 0.0002in-0.0004in (5 – 10 microns)

- Automatic detection of: Seamer clearance, thickness and feeler gauge

- Can sizes supported: 200-603, any height

- Documentation: System saves all audits and adjustments numbers and images

- Output interface: USB