μMeter-SLM ELOVIS

Systems for the accurate measurement of discrete parts from 10mm up to approx. 5m

SKU: SLM

Description

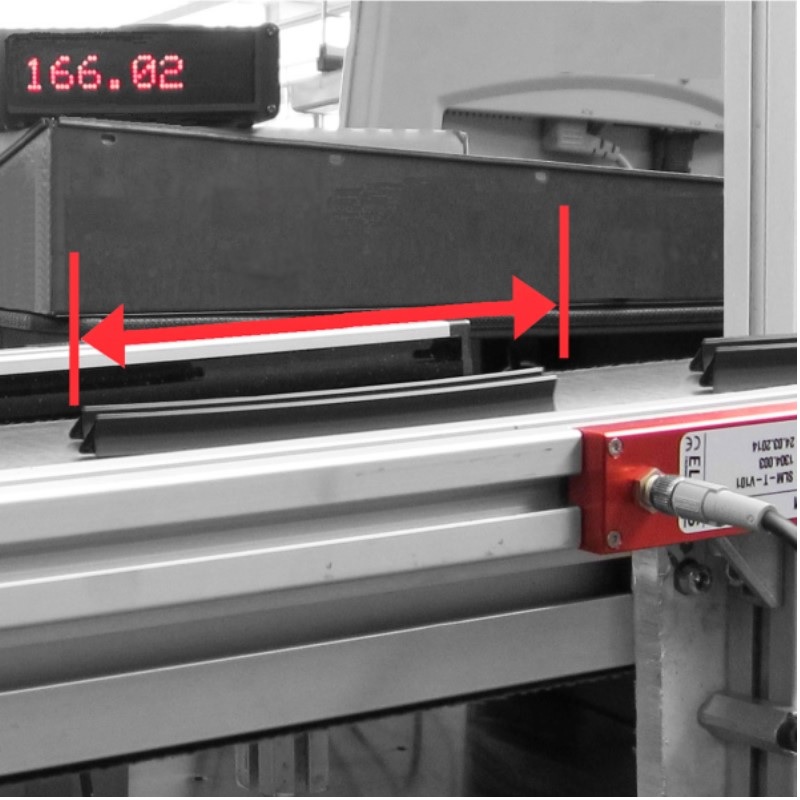

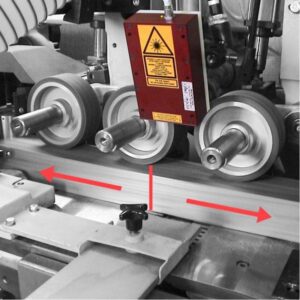

μMETER-SLM systems measure discrete part lengths from approx. 10 mm to nearly 5 m during the longitudinal movement of the material to be measured. SLM systems are usually integrated into the production line following a cutting unit and monitor every item produced at full transport speed. SLM systems are offered as a consistent transmitter and receiver array for different maximum unit lengths and are permanently calibrated ex works. With a typical measurement accuracy of +/- 0.1 mm per meter measuring length despite material movement, the SLM system is unique in the market of serial measurement technology. SLM systems are used for production optimization, good/bad sorting and documentation of the delivery status of discrete parts. SLM systems are maintenance-free, permanently accurate and measure largely independent of material. Typical measurement materials are profiles, tubes, plates, sheets, boards, beams, bolts, … made of the most diverse materials.

Applications

- Pipes and Tubes

- Sealing Profiles

- Hybrid and Rubber Profiles

- Metal Sheets

- Plates and Panels

- Winding Cores

- Rods and Bolts

- System components: Transmitter and receiver arrays

- Measurement material length: 10mm to 126mm (SLM-L0,1) and 10mm to 4,860mm (SLM-L4,8)

- Systematical measurement accuracy: ±0,1mm/m

- Repetitive accuracy: ±0,3mm (confidence interval 1σ)

- SLM arrangement of transmitter and receiver to each other: horizontal, vertical or diagonal

- Measurement distance between transmitter and receiver array: 150mm to 1.000mm

- Interfaces: 1xRS-485

- Available Data: Speed, length, signal quality, status, valid measurement

- Protection class: IP50

- LED Data: 5mW, Infrared