Metal Ends Inspection - INDUSTRIAL PHYSICS EAGLE VISION

The Metal Ends Inspection module inspects damages, roundness and compound on metal can ends. This includes scratches, dents, rust, contamination, compound misapplications and more.

SKU: Metal Ends Inspection

Description

Metal Ends Inspection instrument by Eagle Vision can detect a wide range of defects that commonly occur with can ends. The Metal Ends Inspection module inspects damages, roundness and compound on metal can ends. This includes scratches, dents, rust, contamination, compound misapplications and more. The system is available for high speeds and for several metal can end sizes and types. The system is compact and can easily be installed on both existing and new lines.

This advanced, compact inspection instrument is hygienic in design, easy to install and provides highly accurate detection capabilities due to the smart 3 color light source technology – every light source highlights different defect types reliably. Perfect for end manufacturers who need to assure quality closures.

These are typical defects that can occur on metal ends but Metal Ends Inspection can identify:

• Seaming compound voids and skips

• Seaming compound mispositioning

• Misplaced compound drops

• Oven dirt

• Contamination

• Rust

• Foreign objects

• Out of round / ovality

• Scratches

• Dents

• Smashed curls

• Cut curls

• Curl dents

Smart 3 Color Light Technology

A key feature of the Metal Ends Inspection unit is the three colored light smart technology for identify product defects. Each light color is optimised to identify specific types of defects, allowing for sophisticated and convenient quality assurance checks.

- Blue Light – Optimised for identifying stains or scratches to coatings that expose metal

- Green Light – Optimised for dents and dust particles. This light technology is also ideal for inspections of compound applications.

- Red Light – Optimised for identifying scratches and dents with height information. This light technology is also ideal for inspecting the curl.

• Smart 3 color light source technology – every light source highlights different defect types.

• Very easy to set-up and install, due to circular Region Of Interest (ROI) setup.

• Sensitivity adjustable per Region Of Interest (ROI).

• Highly accurate detection, less than a small dot of a thin contrasting fine liner.

• Detects damages that may erase coating, to cause corrosion.

• Detects foreign objects that can contaminate the canned product.

• Detects rust that can contaminate the canned product.

• Detects compound failures may cause leaking cans.

• Detects curl flange damages that can cause double seam failures and seamer issues.

• Blue dot inspection for blue dot ends (by use of dedicated separate Optical Unit).

• Stainless steel hygienic design.

• Modular design – select and combine camera points by need.

• Robust mounting to the floor – more stability compared to mounting on conveyor with full weight.

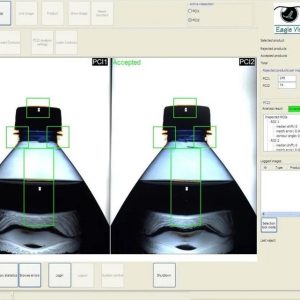

• Easy to use interface – large pictures, large buttons, intuitive navigation.

• Logging of statistics, pictures and data.

• Translations in all languages possible.