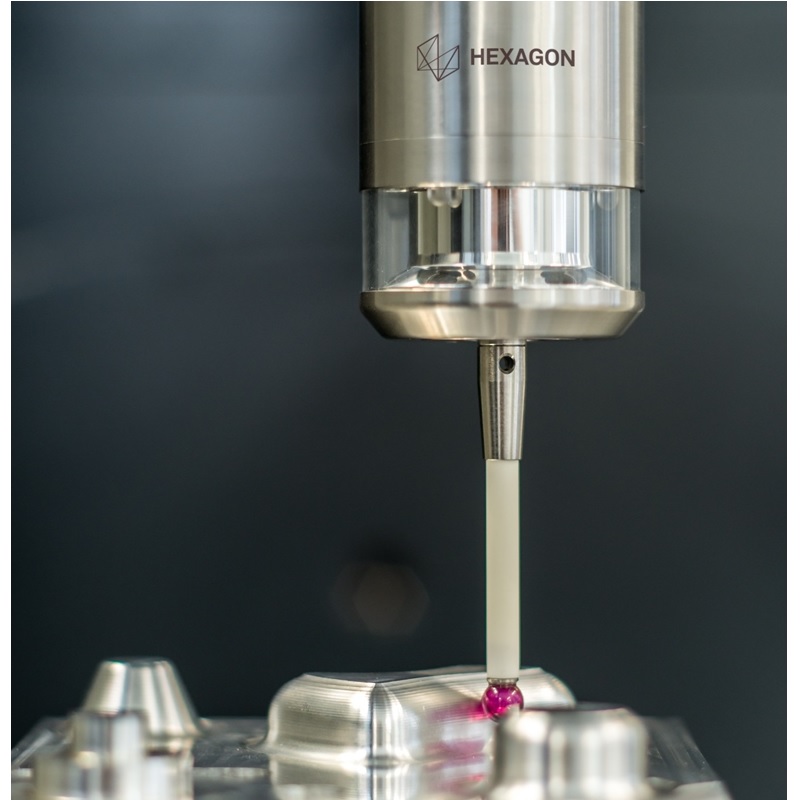

Infrared Probing System IRP40.02 HEXAGON_M&H

The infrared touch probe for mass production by HEXAGONMI-M&H

SKU: IRP40.02

Description

The m&h IRP40.02 infrared touch probe system meets all requirements for measurement on the machine tool. Extreme accelerations, high positioning speeds, constant vibrations, hard tool changes, increased temperatures and aggressive coolants pose no problems for m&h touch probes. M&H’s precision mechanics can continue to switch extremely precisely and without wear for years under all these conditions.

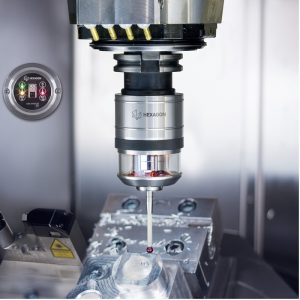

Thanks to its extremely compact and robust design, the IRP40.02 touch probe only needs a very small space on the machine and can also be used for applications in extremely limited spaces.

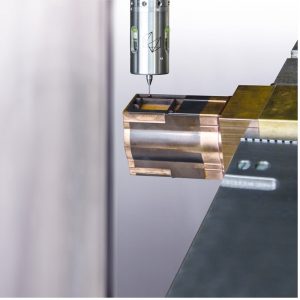

The IRP40.02 shows its real strength in the combination of process reliability and optimised measuring strategy.

Mass production places the highest demands on the manufacturing process. For automated processes, the operator must be able to rely completely on the equipment.

In a machine tool this means a highly-robust touch probe system, secure signal transmission under the most difficult conditions, and unequivocal status displays for quick decision making and intervention in the process. This is the only way to eliminate long service times and error diagnostics. It not only creates trust, but also saves costs.

The IRP40.02 was specially developed for these applications and covers all requirements for use in mass production.

The robust construction is easily up to the task of performing in a rough environment while constantly being doused with coolant and hit by swarf. Intelligent Trigger Evaluation (ITE) technology supports the shortest cycle times without losing process reliability. Fast and precise probing as a result of the one-touch strategy permits the highest degree of precision.

The unprecedented battery life ensures that manual interventions occur less frequently and the automatic process is not disrupted by them. Expensive machine downtime is minimised. This not only reduces process costs, but also operational expenses.

- Sensing Directions: ±X; ±Y; -Z

- Maximum Stylus Overtravel: XY = ±12,5°; Z = -5 mm

- Trigger Force with 50 mm Stylus: XY = 0,8 N; Z = 5,7 N

- Recommended Probing Feedrate: Max. 2000mm/min

- Power Supply: 2x Battery (3,6 V / ½ AA), Standby 12 months

- Maximum Battery lifetime: approx. 800 hrs

- Material: Stainless steel

- Weight without Shank: approx. 235 g

- Unidirectional Repeatability: max. 0.5 μm (2 Sigma) with 50 mm stylus and 254 mm/min probing feedrate

- Sealing: IP68: EN60529 (15 m) tested

- Maximum Probing Frequency: 50 Hz = 50 points/s

- Shock tested: in ±X; ±Y; -Z, 50G for 7ms (5000 times)

- Resonant Frequency Test: Passed

- Temperature Range: Operation: 5°C – 55°C, Storage: 5°C – 70°C